Jotun: Keeping Pace with Sustainability

Jotun: Keeping Pace with Sustainability

Jotun: Keeping Pace with Sustainability

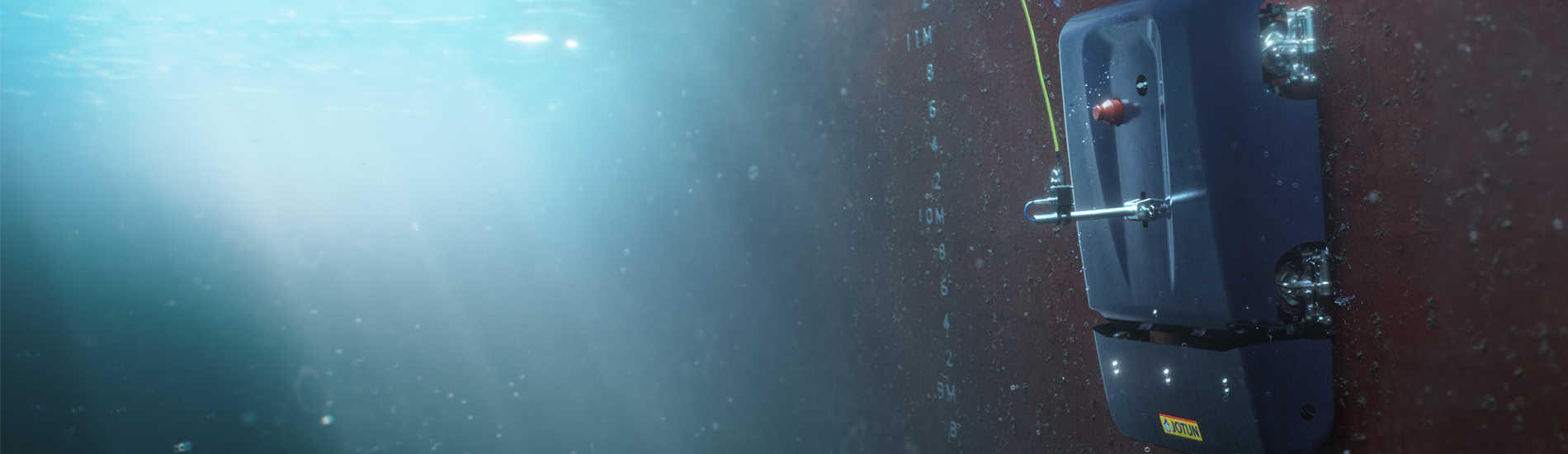

Jotun has considered sustainability and good governance a part of its DNA since it was established in 1926. Whether that is with paints and marine coatings boasting antifouling technology capable of reducing CO2 emissions through fuel savings or innovative products contributing to green building solutions, the company has been at the forefront.

It would have been easy to lose sight of this over the years. Jotun has expanded to more than 100 countries and now employs more than 10,000 people worldwide. Instead, the company’s commitment to conducting business responsibly remains as strong as ever across all markets.

“We’re a family-owned Norwegian company, and this has allowed us to keep the business focused on our values of loyalty, care, respect, and boldness. I think that’s ingrained in everything we do. Today, a lot of this is referred to as sustainability, but for us, it’s just who we are and how we do business at Jotun,” Ms Kristine Anvik Leach, Managing Director at Jotun Thailand, explains. “We don’t have a separate sustainability strategy because it is the fabric of our business strategy and approach.”

However, requirements are changing. Jotun found itself needing to carry on with its sustainable and responsible mindset while needing to measure its performance on something it considers a core tenant of operations.

“Sustainability has been a part of our business for almost 100 years. It is the Penguin Spirit. We do this because we believe it is the right thing to do. The main difference between then and today is now we are being asked to track things in an accurate way,” Ms Anvik Leach states.

She continues, “When you’re starting to document sustainability, it’s a bit painful at first because there are so many numbers that you need to find and learn how to track them. Now, we have the systems in place. We know what we’re tracking. It becomes easier and clearer to see that we’re doing the right things. And having those constantly reminds us that this is the right thing to do.”

The company is always looking to streamline its approach in certain areas. One example is Jotun’s Chemical Policy which sees all products sold worldwide align closely with Europe’s Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH), a standard far higher than what is found in many other countries.

“It doesn’t matter if a chemical is not identified within Thailand as toxic or not good for the environment. If the EU or Norway has already identified that, then we don’t use the chemical in Thailand either,” Ms Anvik Leach proclaims. “Our thinking is if it’s not healthy for Norwegians, it’s not healthy for those living in Thailand or any other local population.”

This has created challenges for Jotun across the value chain. These include monitoring suppliers, working with them to develop standards, meeting evolving customer expectations related to sustainability, and continuing to develop products across all segments that offer superior performance with a reduced impact on the environment.

Supply side

In order for Jotun to be a responsible manufacturer, it needs to work with responsible suppliers. As new legislation is enacted across the world and market expectations rise, the need for robust partnerships at the local and global levels has heightened.

“The focus on tracing parameters of sustainability remains high on the agenda. We source raw materials from global suppliers but also have local suppliers. The approach isn’t simply what we can do on our own premises. We need to understand how we can best track and trace what goes into Jotun products,” Ms Anvik Leach says. “It is not only materials themselves. Working conditions for staff, how a potential partner conducts all aspects of business, and many other considerations are included.”

For Jotun, a supplier saying they are doing the right thing is not enough. Nor is a simple site visit and audit. Relationships with suppliers are shaped over time. For Jotun, a minimum baseline of expectations must be met, but there is also the opportunity to support them in their own sustainability journeys.

“We have certain targets that suppliers must meet. If they don’t initially fulfil these requirements, we can show them where they need to improve and support efforts to become an approved Jotun supplier,” Ms Anvik Leach explains. “This is a way to strengthen local value chains. Partners can visit our site to see how we are doing things. Sharing our best practices is one way to elevate sustainability efforts in the markets we have a presence in.”

Customer concerns

According to Ms Anvik Leach, one of the most notable changes in recent times has come from customers. Their expectations have risen drastically which means Jotun’s commitment to sustainability is now being placed in a greater spotlight.

“It is not simply one segment or one type of customer. Higher expectations from us are seen across the board. In many cases, conducting business sustainability and responsibly is a ticket to play. While it has always been what we do and our focus, more customers now want to understand our efforts on this front,” Ms Anvik Leach states. “The key thing is not to greenwash or shout big claims, but to really show tangible actions, engagements, and activities.”

While Jotun’s clients in the industrial and marine industries have traditionally held sustainability at the forefront of their concerns, customers from another segment are increasingly focused on these issues.

“When it comes to decorative paint and house paint, people are now more invested in sustainability. They are asking questions. They want to know the environmental impact as well as how it can affect the health and wellness of families,” Ms Anvik Leach says. “We don’t sell directly to homeowners but through our business partners. Those business partners are now increasingly interested in sustainability because their customers want to have this information before making a purchase.”

Green Steps

In 2010, the Jotun GreenSteps programme was launched as a way to improve its environmental footprint. Three key areas were highlighted: developing sustainable products and solutions, reducing the footprint of operations, and supporting customers to meet new regulations and achieve sustainability goals.

“It wasn’t that these were new goals, but introducing the Jotun GreenSteps programme was a way for us to make sure our focus was clear,” Ms Anvik Leach notes. “As with many aspects of our sustainability efforts, this was another way for us to better measure what we were doing. To that extent, the program has given us some excellent results since it was implemented.”

The company’s carbon footprint has been reduced by 21 percent, 61 percent of all waste generated is now recycled, energy efficiency improved by 16 percent, and more than 20 percent of energy usage originates from renewable sources.

Powering the future

One example of the Jotun GreenSteps programme in Thailand can be seen with the implementation of a rooftop solar project at its Chonburi facility. The first phase saw more than 1400 solar panels installed. These are capable of generating up to 14 percent of local energy requirements.

“Getting a bigger share of renewable energy for our Thailand operations is important. Becoming more sustainable, obviously in combination with continuously monitoring energy consumption, is a priority.” Ms Anvik Leach points out. “Initially, the investment plan was to go over several years. Together with the management team, we have tried to speed up that process. I think it shows our commitment and dedication to getting a larger share of renewable energy.”

She adds the process of completing such a project in Thailand is straightforward since the country has a high level of competency in installing, designing, and getting solar projects running. However, some other aspects of the process in the country could be improved for businesses wanting to embrace renewable energy.

“I think for the companies that are in Thailand and considering making an investment in renewables, once you’ve made a strategic decision, commit to it. These things now matter to customers and will only grow in importance moving forward,” Ms Anvik Leach says.

Fact Box

- Jotun has been operating in Thailand for more than 55 years

- The Jotun GreenSteps programme was launched in 2010 as a way for the company to improve its environmental footprint

- The company’s chemical policy sees all products sold worldwide align closely with Europe’s REACH standard

- More than 1400 solar panels were installed at Jotun’s Chonburi facility as part of a larger project slated to be completed in 2025

- Globally, Jotun has reduced its carbon footprint by 21 percent

For other interesting articles from our members and chamber activities, please visit our website.